Quality

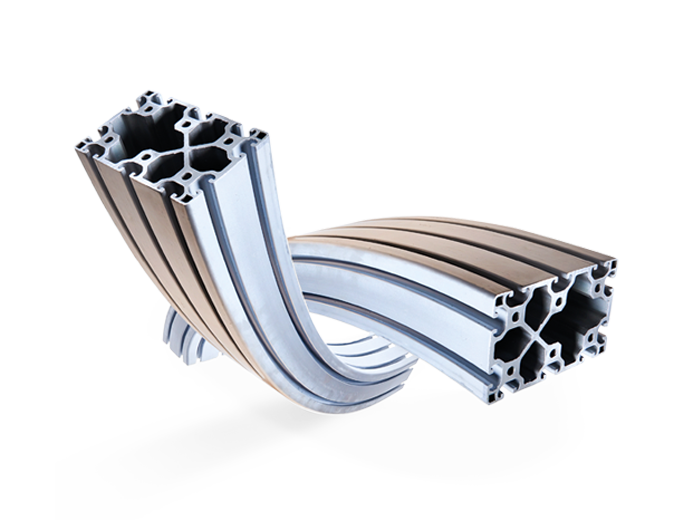

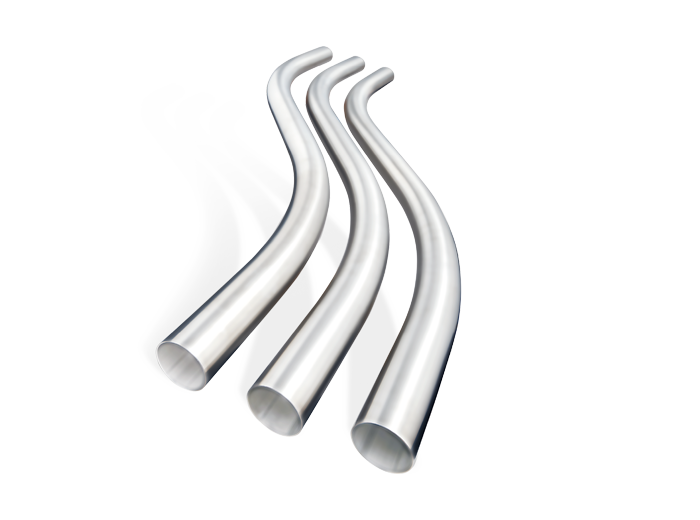

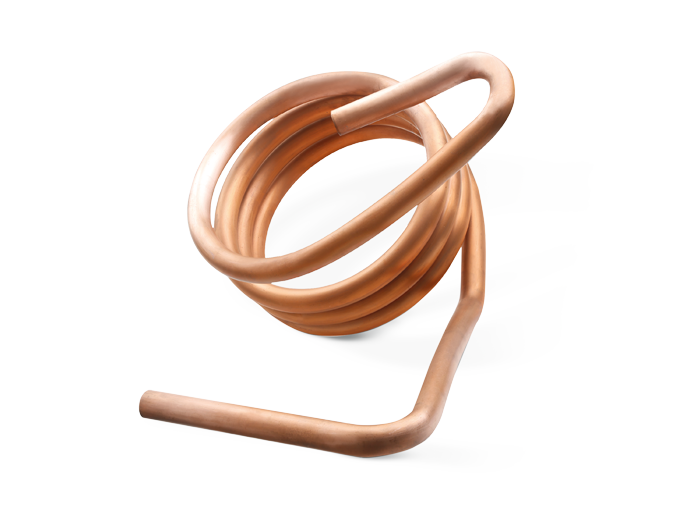

Built on Trust. Delivered with Precision. As one of the UK’s leading tube manipulation specialists, we take pride in producing high-quality, precision engineered components for critical applications.

Our quality assurance processes are supported by advanced inspection and measurement systems:

-

UKAS ISO 9001:2015 Certified

Independently audited and certified, our quality management system ensures every project is delivered with consistency, traceability, and compliance. -

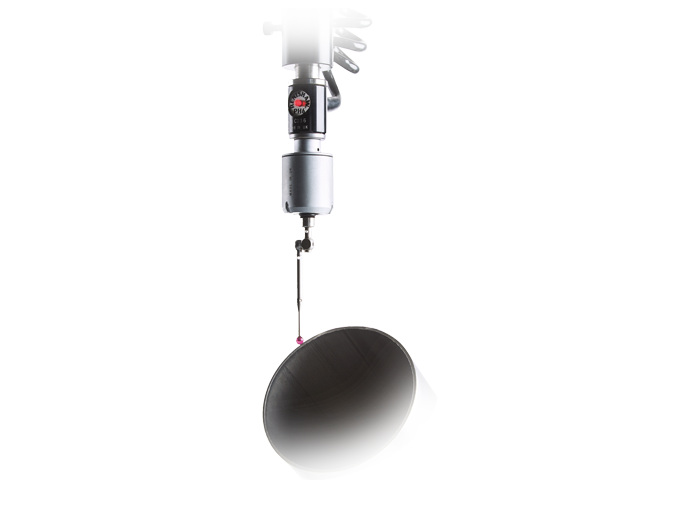

CMM Inspection

We use industry-leading Coordinate Measuring Machines (CMMs) to inspect tubular components with high precision—whether referencing nominal dimensions or CAD data. -

Live Data Feedback to CNC Tube Bending Machines

Our inspection systems are fully integrated with our CNC bending machines, enabling real-time data feedback and adjustments during the bending process—minimising errors and maximising consistency. -

Non-Destructive Testing (NDT)

We offer optional non-destructive testing and reporting to meet specific industry or customer requirements, including detailed inspection reports upon request. -

Annual Calibration

All inspection equipment is calibrated and certified annually to ensure ongoing measurement accuracy and compliance with international standards.

Click Here to Download our latest UKAS ISO 9001 certificate