Quality

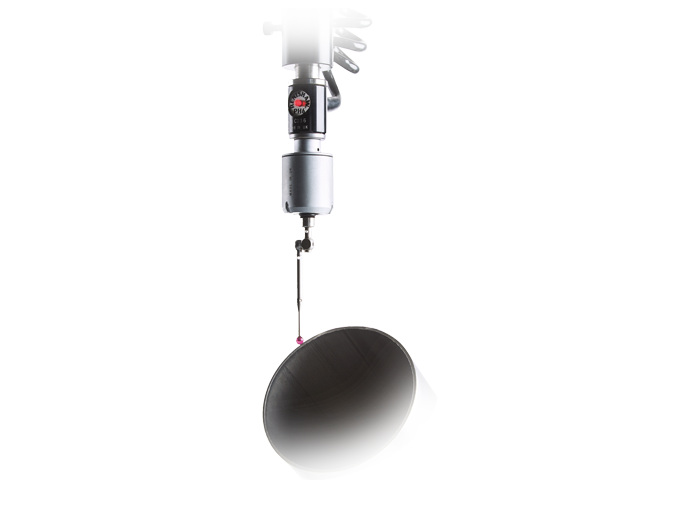

Tubecraft benefits from having the technology to measure and inspect tube and sections to a high accuracy with the use of our industry leading coordinate measuring machines. We have the capability of inspecting tubes against nominal data or CAD models to ensure conformity and quality during the bending processes.

Our CMM inspection machines are networked directly to our CNC bending machines, ensuring that inspected tube data is transferred directly back to the machines and enabling us to make any adjustments required during the bending operation.

We are able to provide tube inspection reports and offer non-destructive testing (NDT) and reporting for our bent tubular components at our customers request.

All inspection machines are calibrated and certified annually and we are accredited to ISO 9001:2015 for the provision of tube manipulation and section bending services.