Design Advice

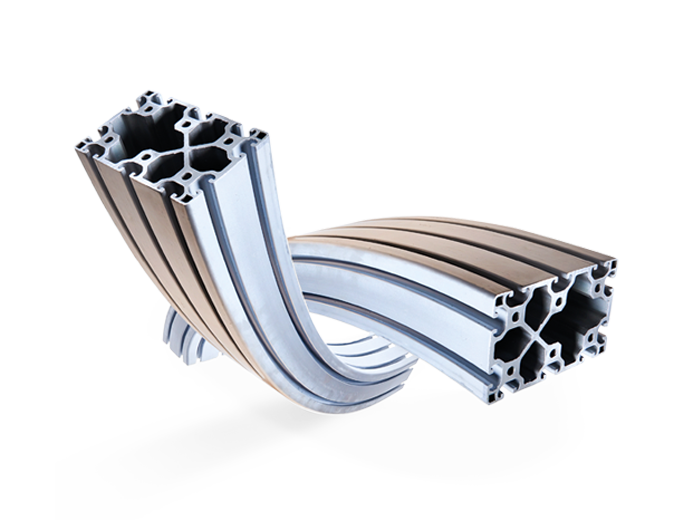

Choosing a CLR (Centre Line Radius)

With one of the largest tooling capacities in the South of England, we are likely to have a bend die to suit your requirements, if we don’t and you require a specific die we are happy to quote to supply this as well. If there is flexibility in the centre line radius we recommend choosing an existing die from our tooling. A rule of thumb is a centre line radius tighter than 1.5 times the tube outside diameter will increase the costs.

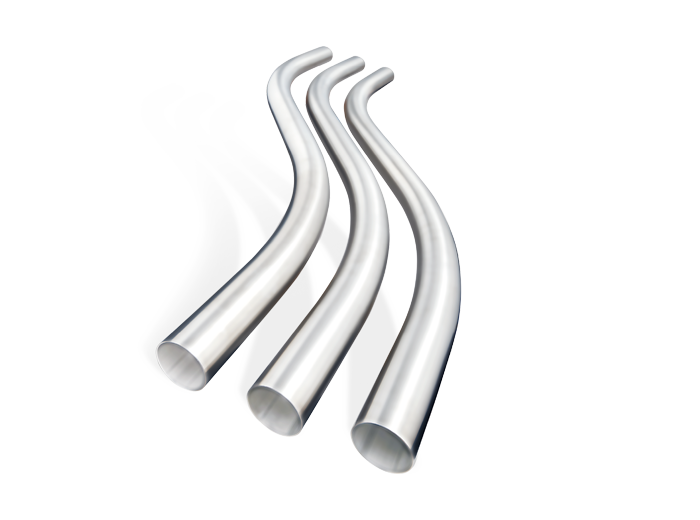

Straights between bends

If your part requires more than one bend there will be a minimum straight between the bends. This is also known as the clamp length. Using our tooling list, you are able to see the clamp length for any size tube and the associated centre line radius.

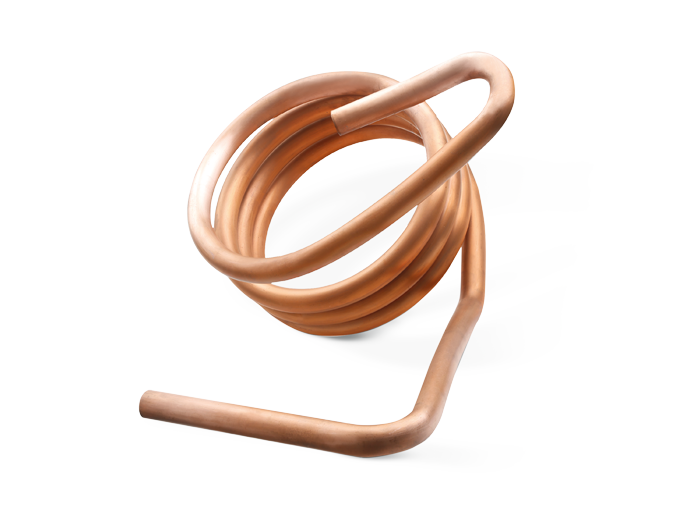

Wall Thickness (W/T)

When designing parts consideration needs to be given to the tube wall thickness, people generally assume by using a thinner wall thickness it will make the part more cost effective. In some cases where components are designed with thin wall tubes on a tight CLR, this often results in increased setup times which can increase the unit cost.

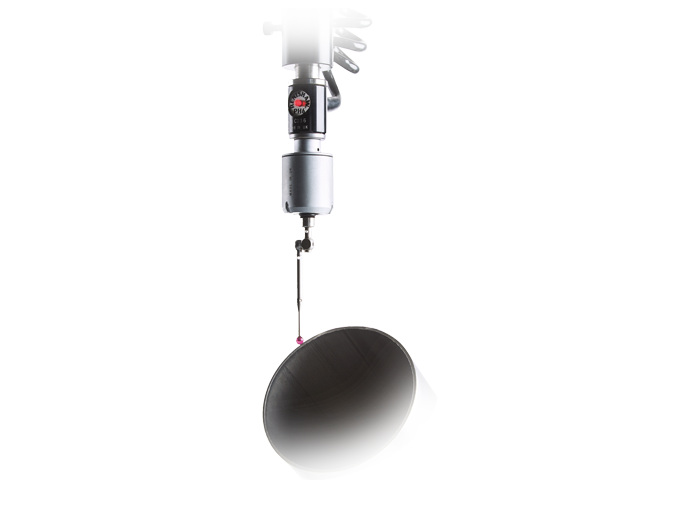

Submitting drawings

When submitting a drawing of your part, some important information is required. This is:

– Outside Diameter (O/D)

– Wall Thickness (W/T)

– Material type

– Material grade

– Preferred Centre Line Radius (CLR)

We can open and use .DWG, .DXF, .STP, .IGES, .SLDPRT and .PDF file formats. These should be emailed to info@tubecraft.co.uk. If you have any problems sending the files or any questions please do not hesitate to contact us on 01590 286080.