March 2018

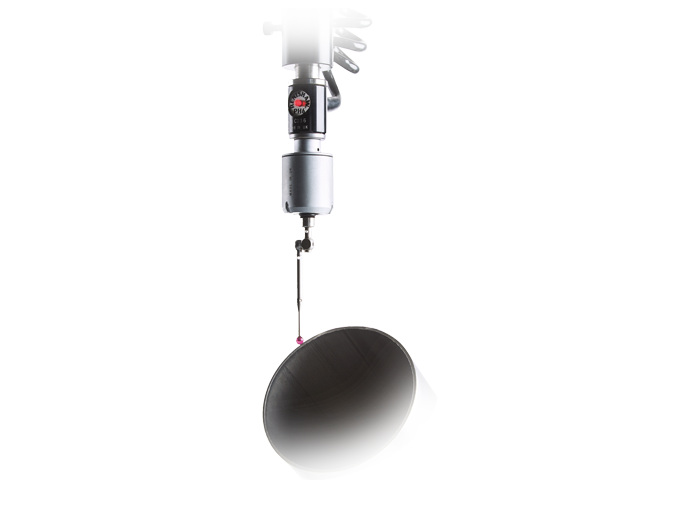

T&T Tubecraft have recently installed a KASTO Automated Tube Storage system for storing all of our stock material. The computer-controlled storage and retrieval system became operational in December 2017, having been systematically populated with tube and other long stock items that was previously held in conventional cantilever racking. The storage cassettes will hold stock material up to 8m in length and the system will hold up to 34 tonnes of material at any one time.

The system has heavily reduced the amount of manual handling , picking and processing time and improved our stock management of our raw material enabling us to be more efficient in our material processing.

Latest News

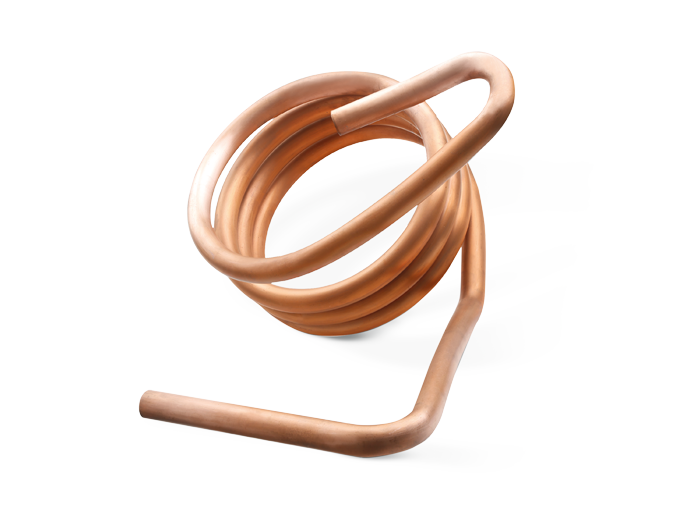

Serpentine Coils – Autoclave sterilisation heat exchanger

🚀 From 6 Months to 7 Days – Problem Solved 🇬🇧 When one of our customers needed replacement serpentine coils for their autoclave sterilisation heat exchanger system, they faced a big challenge:The original machine manufacturer quoted a 6-month lead time. That meant a critical sterilisation system would be out of action for far too long. […]

Power Meets Precision: Heavy Wall Pipe Bending for the Nuclear Sector

At Tubecraft, we’re not just bending precision tubing — we’re pushing the limits of what’s possible with heavy-wall pipe. We recently completed bending trials on 88.9mm x 7.62mm (3” NB SCH 80) 316 seamless stainless steel pipe, using a 110mm CLR on our 130mm CNC electric mandrel bender. The results? ✅ Clean, tight-radius bends✅ Consistent […]

Precision Aluminium Bending Powers Airport Security Innovation

T&T Tubecraft is proud to highlight a recent project that demonstrates our expertise in precision aluminium extrusion bending—a critical component for a leading manufacturer of airport security screening conveyor systems. This bespoke solution was engineered to meet the rigorous standards of continuous airport operation, requiring tight tolerances, exceptional surface finish, and absolute accuracy in forming […]

A busy start to 2025

A busy start to 2025 with the latest batch of bends from 101.6mm O/D x 8mm wall thickness S355 bent on a 4D radius soon to leave our works. These bends are for a major UK manufacture of land moving equipment and are used for their ROPS frames (Roll Over Protection Structure). What Are […]

Stainless steel handrail bending for the Tottenham Hotspur Stadium

As the start of the 24/25 Premier League season is upon us (with the Euros now a distant memory) we look back to when we supplied handrails for the Tottenham Hotspur Stadium.

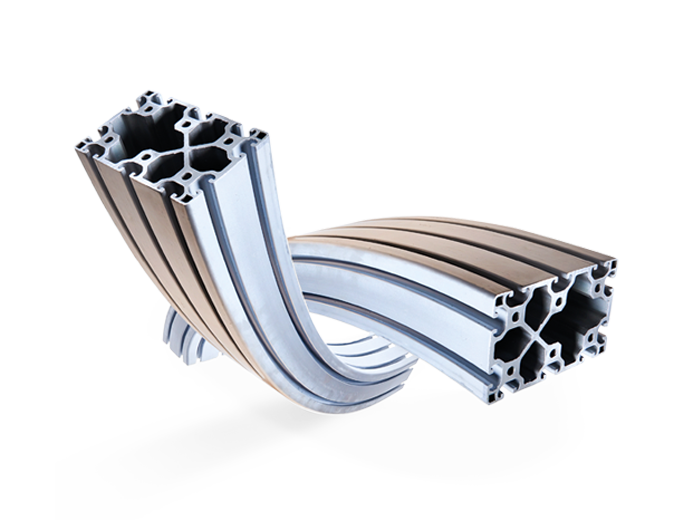

Challenging section bend completed

We have recently been challenged with Section Bending a series of 120mm x 70mm Aluminium slotted box section profiles for a customer that manufactures bespoke Aluminium gates.

Celebrating 75 years in business

In 1949, Tubecraft was founded in Woking and heading for an exciting journey. This year sees us celebrate our 75th year in business. Now based in Lymington, our family-run British company prides itself on offering the largest range of tube bending services in the South of England. Our team is built with innovative, flexible and […]

We are closed for the Christmas holiday period

It is that time of year again where our manufacturing headquarters will close for the Christmas holidays. This year has seen us undertake some exciting projects including one of our products heading for Mexico, upgrading with our brand new all-electric high power dual stack CNC tube bending machine and also installing 270 solar panels on […]

Tubecraft now powered by 270 solar panels!

Here at Tubecraft all our bends are created at our main headquarters in Lymington, Hampshire. Recently, we have undergone the installation of a 96kw solar power system that will allow us to generate enough solar for our high energy needs. The 96kw is delivered by 270 solar panels on the roof of our main manufacturing […]

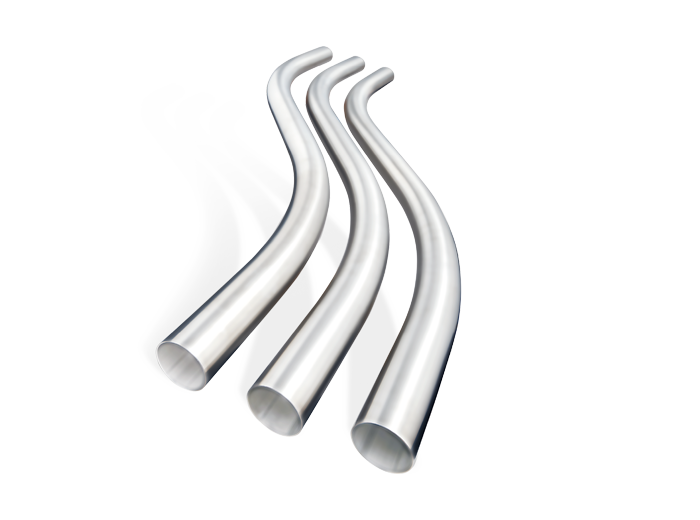

Mandrel Bending of Tube and Pipe for Pneumatic Conveying

Smooth Flow Path: Mandrel bending minimizes deformation and wrinkles on the inner surface of the bend. This results in a smoother flow path for the conveyed material, reducing the risk of blockages and turbulence that could affect conveying efficiency. Consistent Diameter: Since the mandrel provides internal support, the pipe retains a more consistent diameter throughout […]