Ai ChatGPT and Mandrel Tube Bending

As an interesting exercise, and always wanting to keep up with the latest technology we thought we would put Ai ChatGPT to the test on how to solve mandrel tube bending issues. Here’s the response from Ai Chat GPT.

To solve mandrel bending issues, you can take several steps to identify the problem and address it accordingly. Here are some general guidelines to help you solve common mandrel bending issues.

1. Analyze the Problem:

Carefully examine the bent tube and identify the specific issue you are facing. Common problems include wrinkling, collapsing, ovality, distortion, springback, or surface damage. Take note of the specific areas or sections where the problem occurs. This will help you narrow down the potential causes and solutions.

2. Review Bending Parameters:

Evaluate the bending parameters such as bend angle, bend radius, mandrel size and position, bending speed, and feed rate. Ensure that they are appropriate for the tube material, diameter, and wall thickness. Check if any parameter adjustments can be made to mitigate the issue. For example, reducing the bend speed or adjusting the mandrel position may help alleviate wrinkling or collapsing.

3. Assess Mandrel Support:

Verify that the mandrel is properly positioned and supported along the entire bend length. Inadequate mandrel support can lead to wrinkling, collapsing, or ovality. Adjust the mandrel ball size or design, if possible, to distribute the pressure more evenly and reduce tube deformation.

4. Consider Tube Material Properties:

Different tube materials have varying properties, including ductility, work hardening characteristics, and springback tendencies. Consider the specific material properties of the tube you are bending. If the tube material is prone to work hardening or has high springback, you may need to anneal it before bending or adjust the bend allowances and angles accordingly.

5. Review Lubrication:

Ensure that proper lubrication is applied to reduce friction during bending. Insufficient lubrication can cause surface damage or increase the forces exerted on the tube, leading to deformation. Adjust the lubrication method or type if necessary to improve the bending process and reduce friction-related issues.

6. Consult Experts:

If you are unable to identify the cause of the problem or the issue persists, it may be beneficial to seek guidance from experts or contact the manufacturer of the bending equipment. Consulting with experienced tube bending specialists can provide valuable insights and solutions tailored to your specific situation.

Remember that troubleshooting mandrel bending issues can be complex and may require adjustments in various aspects of the bending process. It’s important to experiment, make incremental changes, and carefully monitor the results to determine the most effective solution.

The devil’s in the detail with tube bending but it is a useful summary and we are pleased to see that Ai ChatGPT comes to the conclusion that if all else fails then consult the experts!

Please contact us for any of your tube bending requirements.

info@tubecraft.co.uk

Latest News

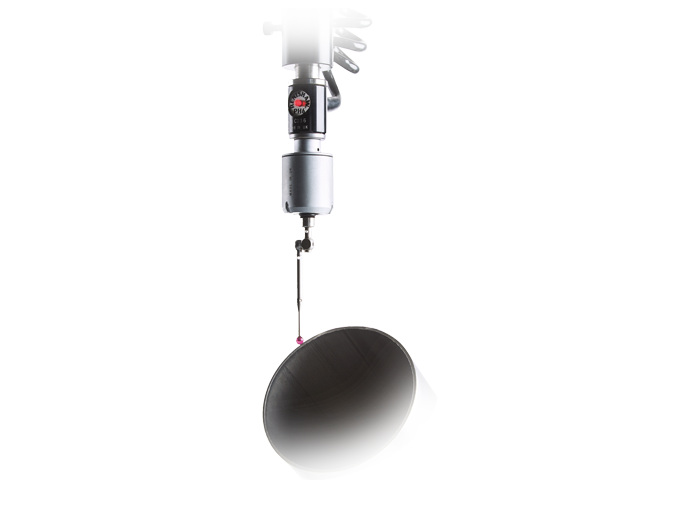

Stainless steel handrail bending for the Tottenham Hotspur Stadium

As the start of the 24/25 Premier League season is upon us (with the Euros now a distant memory) we look back to when we supplied handrails for the Tottenham Hotspur Stadium.

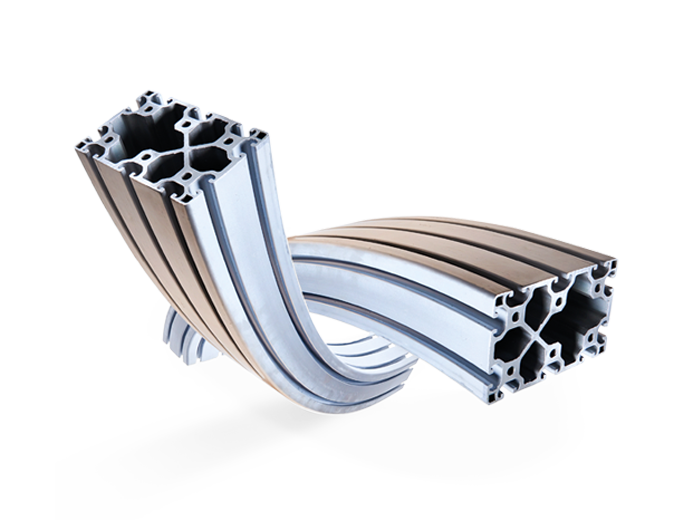

Challenging section bend completed

We have recently been challenged with Section Bending a series of 120mm x 70mm Aluminium slotted box section profiles for a customer that manufactures bespoke Aluminium gates.

Celebrating 75 years in business

In 1949, Tubecraft was founded in Woking and heading for an exciting journey. This year sees us celebrate our 75th year in business. Now based in Lymington, our family-run British company prides itself on offering the largest range of tube bending services in the South of England. Our team is built with innovative, flexible and […]

We are closed for the Christmas holiday period

It is that time of year again where our manufacturing headquarters will close for the Christmas holidays. This year has seen us undertake some exciting projects including one of our products heading for Mexico, upgrading with our brand new all-electric high power dual stack CNC tube bending machine and also installing 270 solar panels on […]

Tubecraft now powered by 270 solar panels!

Here at Tubecraft all our bends are created at our main headquarters in Lymington, Hampshire. Recently, we have undergone the installation of a 96kw solar power system that will allow us to generate enough solar for our high energy needs. The 96kw is delivered by 270 solar panels on the roof of our main manufacturing […]

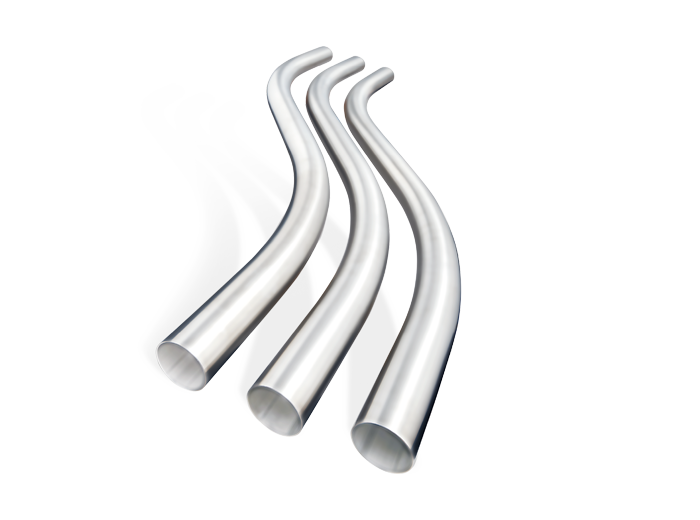

Mandrel Bending of Tube and Pipe for Pneumatic Conveying

Smooth Flow Path: Mandrel bending minimizes deformation and wrinkles on the inner surface of the bend. This results in a smoother flow path for the conveyed material, reducing the risk of blockages and turbulence that could affect conveying efficiency. Consistent Diameter: Since the mandrel provides internal support, the pipe retains a more consistent diameter throughout […]

An Introduction to Section Bending

Section Bending, also known as profile bending or section rolling, is a metal forming process used to bend or curve structural shapes and profiles into specific shapes or radii. Unlike section rolling, which primarily focuses on changing the cross-sectional shape of the material, section bending is all about altering the curvature of the material while maintaining its original […]

Ai ChatGPT and Mandrel Tube Bending

As an interesting exercise, and always wanting to keep up with the latest technology we thought we would put Ai ChatGPT to the test on how to solve mandrel tube bending issues. Here’s the response from Ai Chat GPT. To solve mandrel bending issues, you can take several steps to identify the problem and address […]

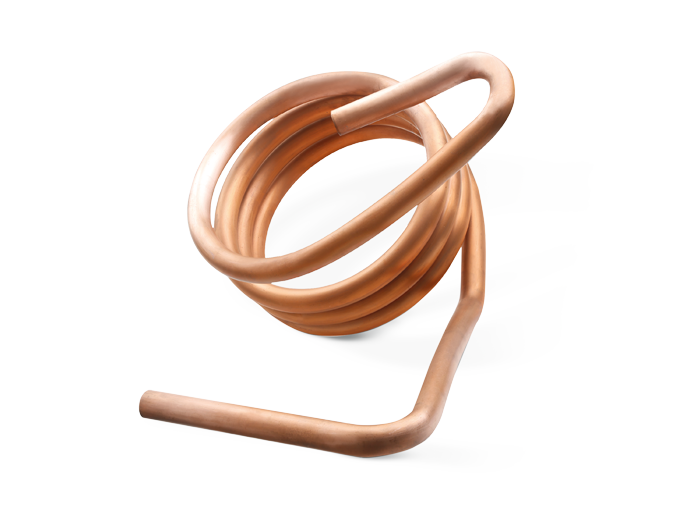

One of our latest productions is heading to Mexico!

One of our latest productions is heading to Mexico! Here at Tubecraft, we have produced these coils with a 800mm PCD from Copper tube with a 63.5mm O/D x 3.25mm wall thickness that will be used to distil tequila for a distillery equipment manufacturer. Approached due to our highly bespoke service and capabilities we produce […]

Tubecraft commissioned to produce cooling coils

Recently, Tubecraft were commissioned to produce a batch of cooling coils for a customer that supplies ejectors to the water and processing industry. We have many years of experience in coiling and working with many sectors including the brewing, chemical, scientific, and process engineering industries to name just a few. For this project the cooling […]